ISEE, a leader in autonomous vehicle technology, has recently made significant strides in the logistics industry with the commercial deployment of the world’s first fully autonomous truck yard. This groundbreaking achievement marks a transition from experimental pilots to a fully operational system at a Fortune 100 customer’s site in Texas. Alongside this deployment, ISEE has unveiled an advanced AI-powered trailer auto-coupling system, further enhancing the efficiency and safety of yard operations.

Autonomous truck yard deployment

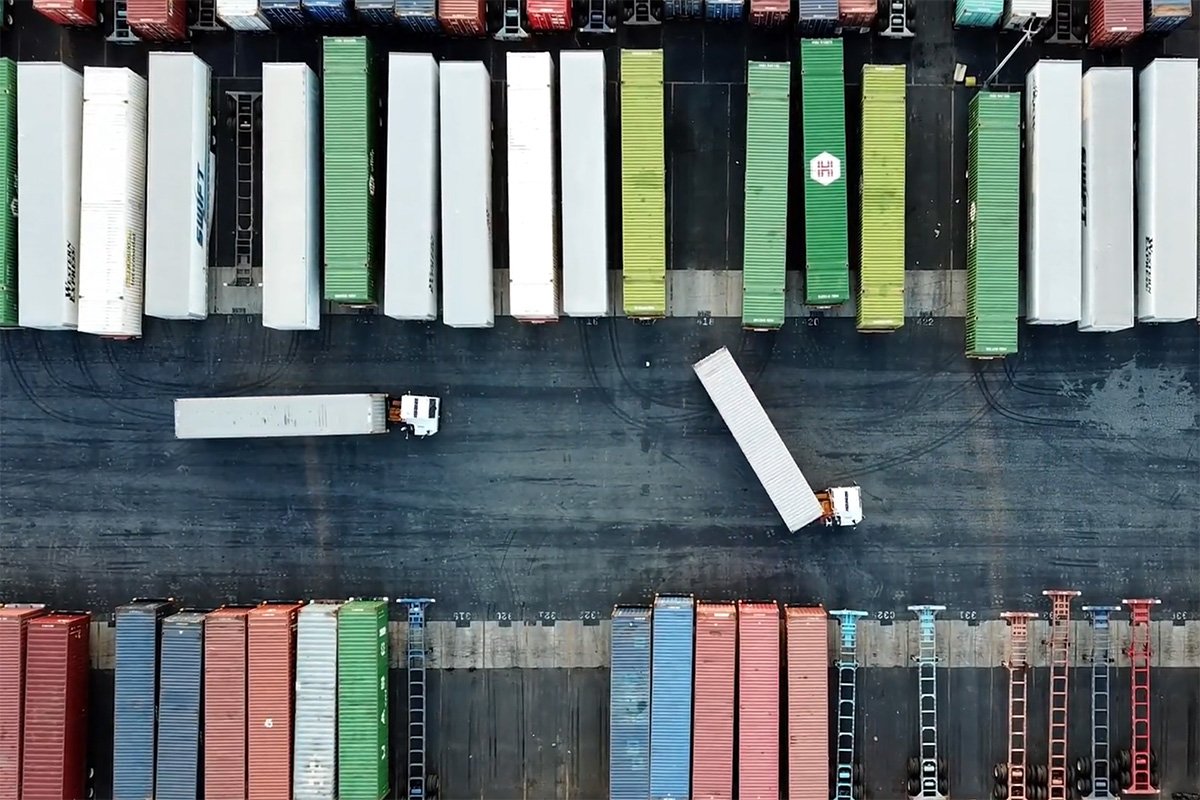

ISEE’s deployment covers a sprawling 1.7 million square foot distribution center equipped with 750 trailer staging bays. The autonomous yard trucks operate seamlessly across all shifts, regardless of weather conditions. This innovation addresses several critical challenges in the logistics industry, including safety, efficiency, and labor shortages.

Enhanced safety

Transportation and warehousing industries have some of the highest rates of worker injuries, particularly from being struck by equipment. ISEE’s autonomous yard trucks are designed to mitigate these risks by eliminating human error. Advanced sensor technologies and sophisticated algorithms ensure precise and cautious movements, significantly reducing the potential for accidents and collisions.

Increased capacity and labor efficiency

The American Trucking Association projects a shortage of 160,000 truck drivers in the US by the end of this decade. This labor shortage poses a significant threat to the supply chain. ISEE’s autonomous trucks alleviate this issue by providing consistent and reliable yard operations without the need for human drivers. This not only enhances operational capacity but also provides facility managers with the assurance of consistent staffing.

Seamless integration

ISEE’s autonomous truck yard integrates effortlessly with existing Yard Management Systems (YMS), Warehouse Management Systems (WMS), and overall facility operations. No additional infrastructure is required, allowing operators to continue using their current systems to request material moves, which are then executed by the autonomous trucks.

Workforce development

Despite the push towards automation, ISEE is committed to workforce development. The deployment of autonomous yard trucks opens up new opportunities for training and upskilling transportation workers, ensuring they can manage and maintain these advanced systems.

AI-powered trailer auto-coupling system

In addition to the autonomous truck yard, ISEE has introduced an AI-powered trailer auto-coupling system, designed to further streamline logistics operations. This system was showcased at the Manifest supply chain technology event.

Advanced robotic integration

The auto-coupling system features a six-axis robotic arm attached to the back of the autonomous truck cab. Utilizing AI, the system autonomously identifies the precise locations and orientations of trailer air connectors for both service and parking brakes. This capability is crucial given the variability in location, orientation, and type of gladhands across different trailers.

ISEE’s system, trained on data from over 10,000 operational moves, autonomously connects the airbrake lines without requiring any trailer modifications, adapters, markers, or remote control. This autonomy is achieved through generative AI models for data augmentation and feature generation, ensuring the system’s adaptability to diverse conditions.

Safety and efficiency benefits

Automating the trailer coupling process eliminates the need for drivers to step out of the cab to manually connect and disconnect trailer air lines. According to the U.S. Bureau of Labor Statistics, nearly 30% of injuries in the trucking industry occur during such activities. The automated system mitigates these risks, thereby enhancing overall safety.

ISEE’s robotic arm mirrors human dexterity, adeptly handling gladhands in various positions. This end-to-end AI approach ensures consistent and reliable operation across different trailer types and environmental conditions.

Flexible automation solutions

ISEE’s trailer auto-coupling technology complements its existing solutions, which include a standardized trailer adapter for consistent connector locations across a fleet. This flexibility allows customers to choose their preferred level of automation, whether they manage their fleet or utilize a captive pool of trailers.

Conclusion

ISEE’s advancements in autonomous yard trucks and trailer auto-coupling systems represent significant progress in the logistics industry. By enhancing safety, efficiency, and capacity, these technologies address critical challenges and pave the way for a more automated and reliable supply chain. As the industry continues to evolve, ISEE’s innovative solutions will likely play a pivotal role in shaping the future of logistics.

Source: ISEE