Wheels are integral to the design of vehicles, ranging from cars and trucks to bicycles and wheelchairs. While their circular shape and robust design allow for efficient movement on smooth surfaces, they often fall short when confronted with uneven or obstacle-laden terrains. For individuals relying on wheelchairs, this limitation significantly reduces their mobility, often confining them to paved roads or accessible environments. Similarly, mobile robots face challenges navigating rough terrains, limiting their practical applications. However, a recent breakthrough in wheel technology, inspired by the surface tension of liquid droplets, may hold the key to overcoming these obstacles.

A deeper look into the problem

Navigating rough terrain is a complex challenge for wheels. Traditional wheels, whether on vehicles, wheelchairs, or robots, struggle with maintaining stability and smooth motion when encountering bumps, rocks, or other obstacles. This issue is particularly significant for those using wheelchairs, as they are often confined to smooth paths and pavements. The same challenge extends to mobile robots designed to explore or work in rugged environments, where traditional wheels limit their operational capabilities.

Track-based locomotion systems have been employed to address these issues. By increasing the contact area between the vehicle and the ground, these systems provide better traction over rough terrains. However, this comes at the cost of increased friction and energy consumption, making them less efficient for certain applications. Additionally, these systems are often bulky and slow, which can be a significant drawback in situations requiring speed and agility.

Another alternative has been the use of airless or non-pneumatic tires. These tires are designed to resist punctures, leaks, and blowouts, making them more durable for harsh environments. However, their stiffness reduces their ability to deform and adapt to uneven surfaces, which can be problematic when encountering high obstacles.

The inspiration: Surface tension of liquid droplets

The latest innovation in wheel technology draws inspiration from a concept found in nature: the surface tension of liquid droplets. Surface tension is the result of cohesive forces between molecules at the surface of a liquid, which cause the liquid to minimize its surface area and form a shape with the least energy—typically a sphere or droplet. This principle led researchers to develop a wheel that can adjust its shape in real-time, similar to how a liquid droplet maintains its form under various conditions.

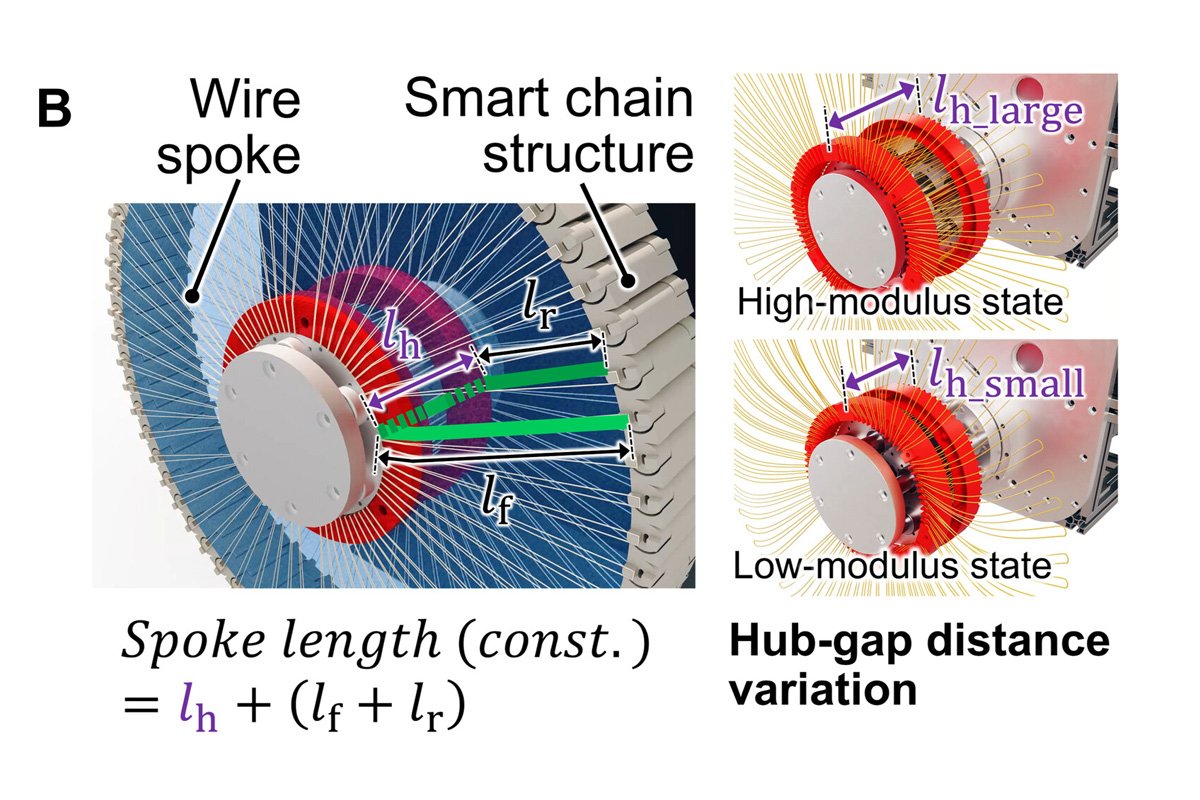

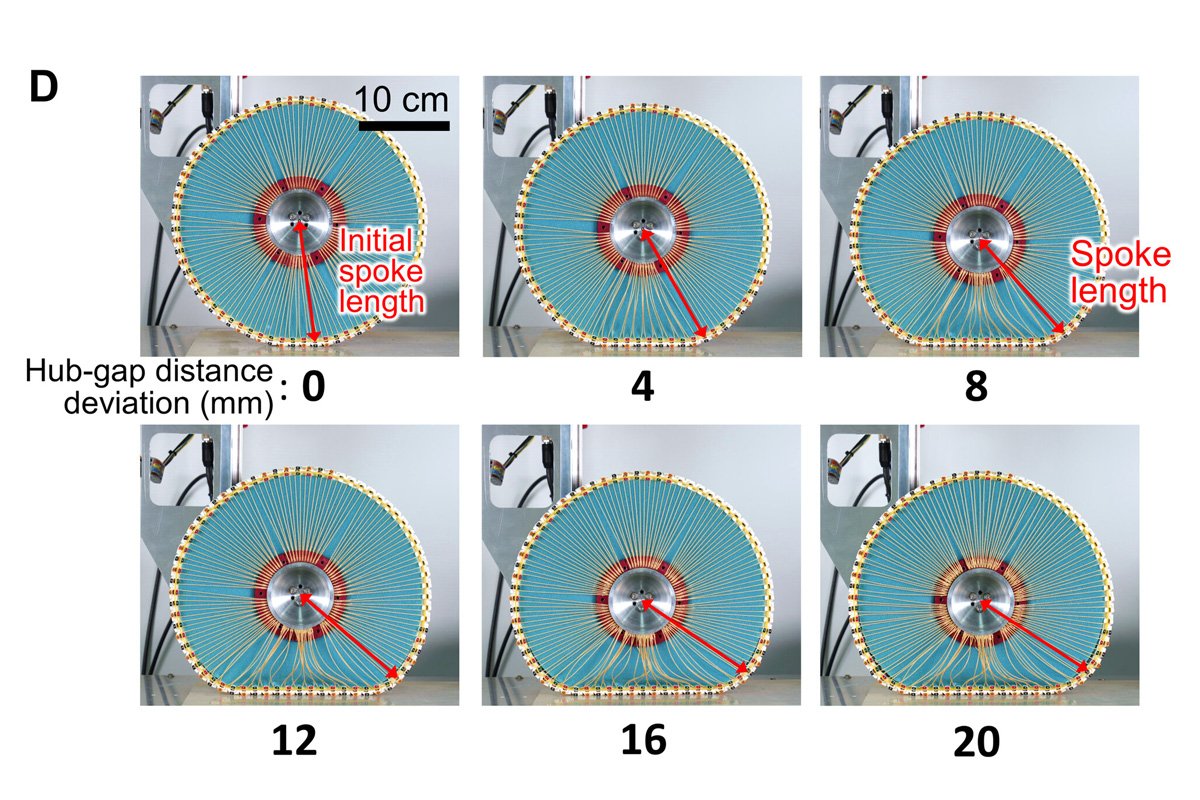

The new wheel design incorporates a “smart chain structure” made up of blocks connected by wire spokes to a central hub. By adjusting the distance between the two sides of the hub, the length of the spokes can be varied, which in turn alters the shape of the wheel. When the hub-gap is increased, the spokes shorten, pulling the chain of blocks inward to form a circular wheel ideal for smooth, quick locomotion. Conversely, reducing the hub-gap lengthens the spokes, allowing the wheel to deform and adapt to obstacles, effectively increasing its surface area in contact with the ground.

Practical applications and testing

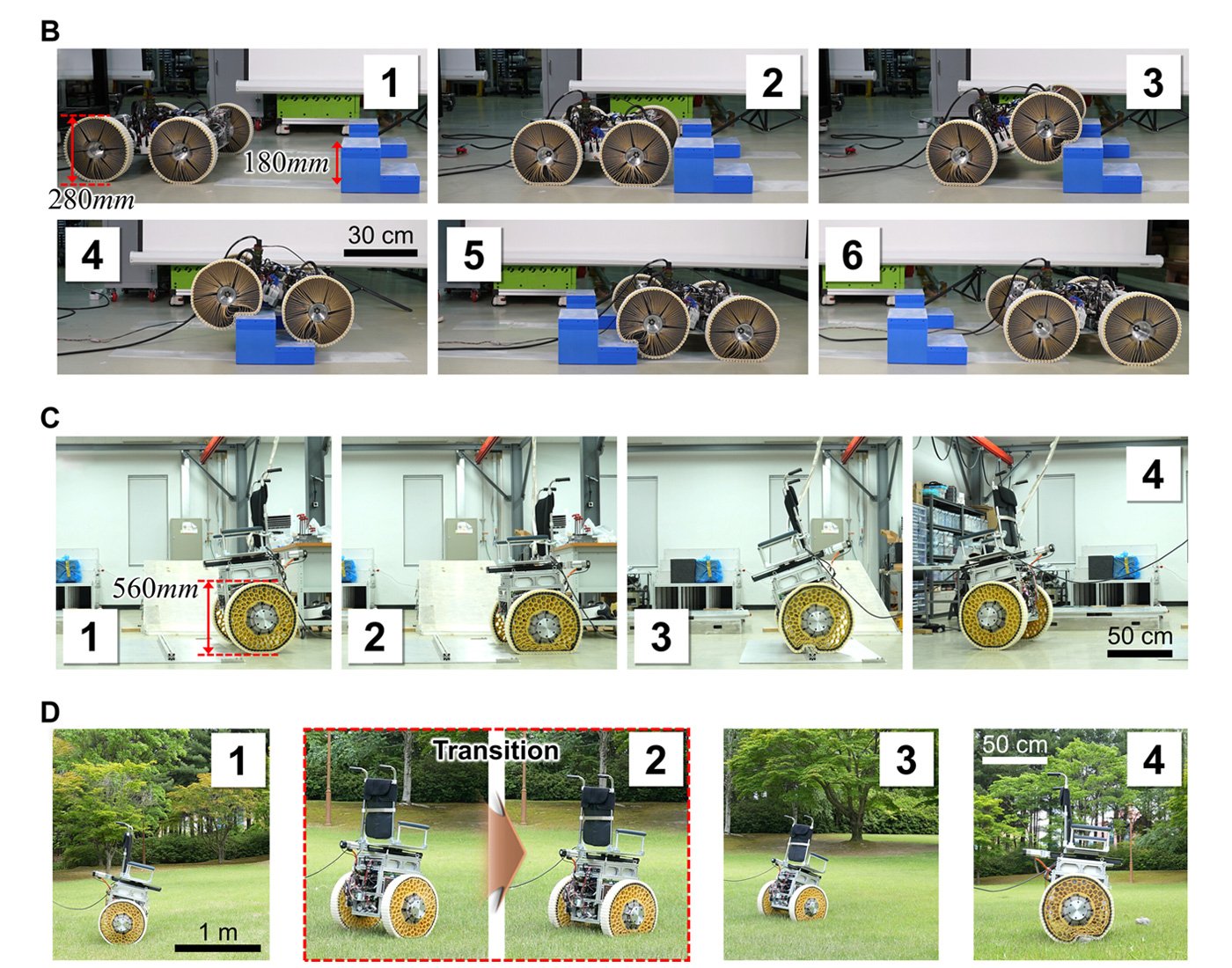

To validate their design, the researchers tested this adaptable wheel in both a two-wheeled wheelchair and a four-wheeled vehicle. The results were promising: both vehicles could navigate over obstacles and rough terrains that were 1.2 times higher than the wheel’s radius. This adaptability could revolutionize mobility for wheelchair users, offering them the ability to traverse environments previously deemed inaccessible.

However, as with any new technology, there are challenges to be addressed. During testing, researchers observed that dust and small particles tended to accumulate between the blocks of the smart chain, leading to potential damage. This is a common issue in mechanical systems exposed to the elements, and it underscores the need for further refinement. The research team is already working on adding a protective cover to the wheel, which would mitigate this problem and extend the wheel’s durability in real-world conditions.

Real-world implications

The potential applications of this adjustable wheel are vast. In the field of mobility aids, such as wheelchairs, this technology could significantly enhance the independence and freedom of movement for users. No longer confined to smooth surfaces, wheelchair users could navigate parks, trails, and other uneven terrains with greater ease. This could open up new possibilities for outdoor activities and social interactions that were previously out of reach.

Similarly, for mobile robots, the ability to traverse rough terrains efficiently could expand their utility in fields such as agriculture, search and rescue operations, and exploration. For instance, robots equipped with these wheels could more easily navigate through debris in disaster-stricken areas, reaching locations that are inaccessible to traditional wheeled or track-based robots.

A practical perspective

Having spent time with a family member who relies on a wheelchair, I’ve seen firsthand how limited their mobility can be when it comes to uneven terrain. Simple activities like going for a roll in the park can turn into a challenging ordeal, with every bump and slope posing a potential risk. The idea that a wheelchair could adapt its wheels in real-time to overcome these obstacles is not just innovative; it’s practical and could make a tangible difference in the lives of many. Similarly, for those working in fields requiring robotic assistance, this wheel technology could mean the difference between success and failure in critical missions.

Source: Science Robotics